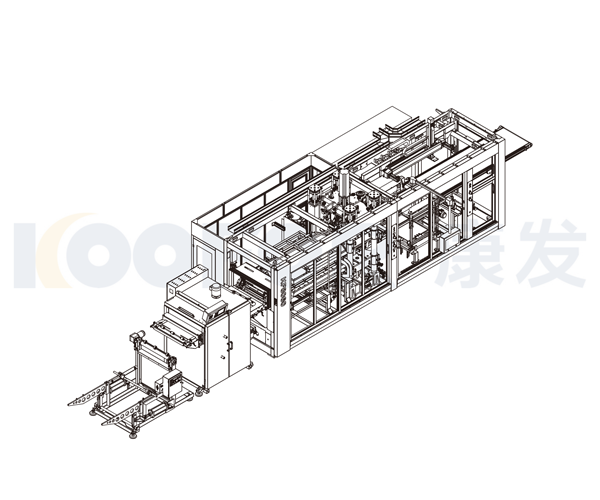

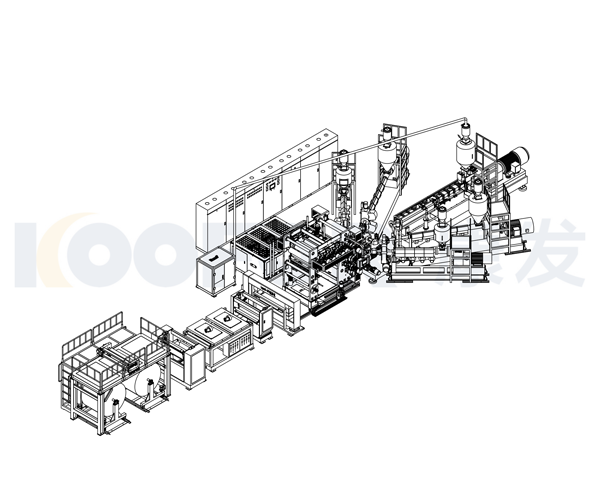

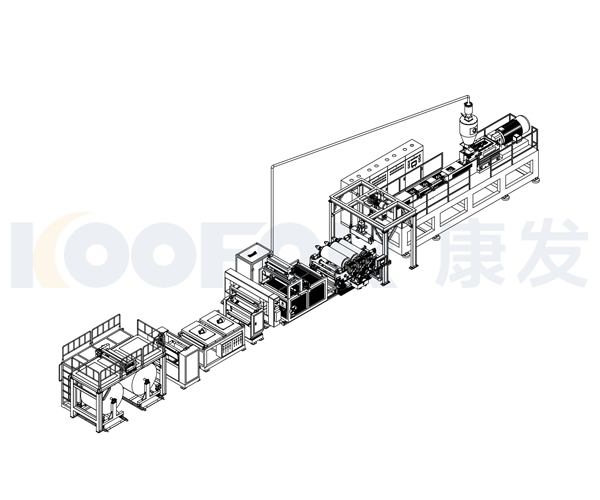

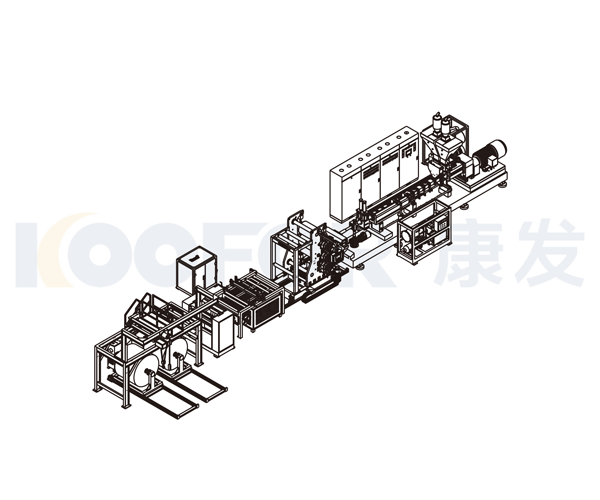

Features:

◎ The average power consumption per ton of finished sheet can be as low as 220kWh.

◎ It is suitable for extrusion production of PP, PE blend, PP low melting finger material and 50% crushing material.

◎ PP products produced by this equipment have higher output, better transparency, more uniform thickness and more stable forming. Mainly through the following three critical control points:

a. Adopt low temperature and high speed extrusion process to make the material fully plasticized and mixed.

b. Carry out melt metering control, realize closed loop with extruder, and extrusion pressure is more stable.

c. With precision nine-roll calender technology, the sheet can be fully cooled and shaped while being extruded at high speed.

◎ Optional online film coating device, to produce high barrier performance lock fresh box (gas box) packaging products.

The net changer adopts the double column circular long acting filter, the single net changing time can be extended to 50-100 hours.

◎ The whole line adopts man-machine interface display, equipped with temperature module management, one-button speed up and other functions, more convenient operation.

◎ The frame adopts low center of gravity structure and heavy steel material, which makes the machine more stable and the sheet extrusion more stable.

◎ Large winding diameter (up to 1500mm), equipped with frequency conversion drive, constant tension control, so that sheet winding more orderly.

21pla.com

21pla.com